INFORMATION AND SPECIFICATIONS

All Brew Cave® walk-ins are constructed of prefabricated, precision-formed, modular panels designed for accurate, rapid field assembly. Brew Caves® are test assembled at the factory for quality assurance.

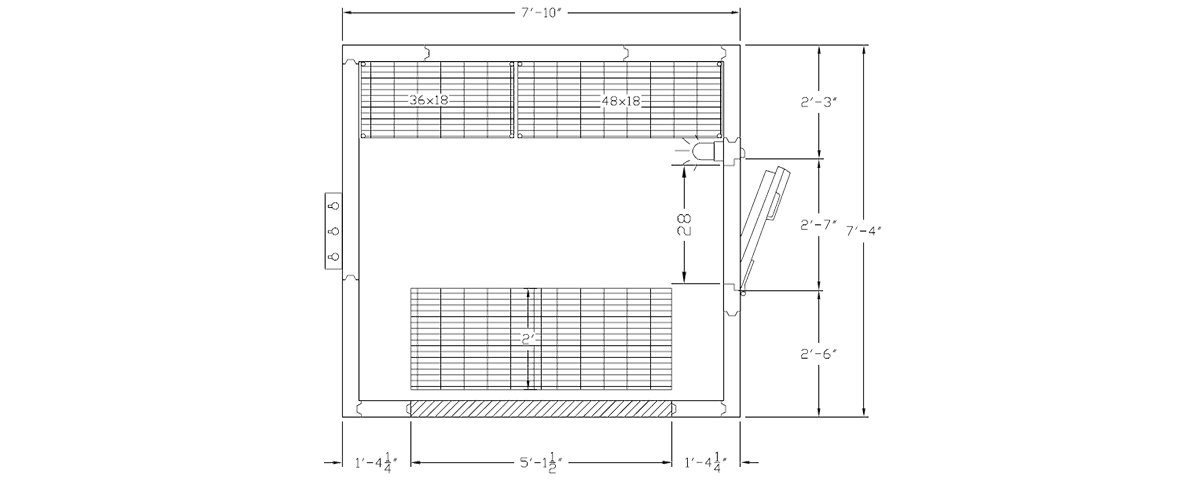

DRAWINGS AND INSTRUCTIONS

Each walk-in includes a set of installation instructions and a layout drawing. All panels have a panel identification number corresponding with the lay-out drawing to facilitate rapid and accurate field erection.

PANEL CONSTRUCTION

Each panel consists of inner and outer metal skins, a 4″ insulation core, and equipped with cam-action locking devices. The locking devices are operable from inside the walk-in. A hex wrench to operate these cams is supplied. Press-fit plug buttons are provided to seal the wrench holes after assembly is complete. The construction of Brew Cave’s® walk-ins is approved by the National Sanitation Foundation International and will bear the NSF® Seal of Approval.

Panels are connected to one another by placing the tongue of the insulation core of one panel into the groove of the core insulation of the adjacent panel. The resultant tongue and groove joint is sealed at both sides by double barreled NSF® approved gaskets. In order to avoid future swelling and mold formation, no wood is used in the manufacture of the tongue and groove panel profile.

PARTITIONS

When specified, walk-ins may be divided into compartments by the use of panels that are constructed in accordance with the specifications for all panels.

FLOOR SCREEDS

Floor screeds will be provided for all floorless walk-ins. The screeds will be vinyl and have NSF® approved cove both inside and out.

PANEL FINISH

The following metal panel finishes available for interior or exterior walls, ceilings and exterior floors are:

• 26 gauge stucco embossed galvalume

• 26 gauge bright stucco embossed galvanized steel

• 26 gauge white stucco embossed galvanized steel

• 26 gauge tan stucco embossed galvanized steel

• 24 gauge smooth stainless steel Interior floors (When specified)

• 22 gauge smooth stainless steel

• 20 gauge smooth galvanized steel (used for use with quarry tile application)

• 24 gauge smooth white galvanized steel

INSULATION

Based on customer preference panel insulation may be Extruded Polystyrene, manufactured in an HFC and CFC free process, made from 60% recycled materials and 100% recyclable. Door insulation may be Polyurethane. Or panel insulation may be foamed in-place polyurethane, manufactured with a HFC and CFC free process.

Coolers – Extruded Polystyrene

All wall and ceiling insulation will be 4” thick, high quality, rigid extruded polystyrene, 1.6 lb density. K factor of not more than .139 and an R-factor of not less than 7.2 per inch, initial fresh R-28.8 minimum total wall R factor. Vapor transmission will be less than 1 perm and foam core material must meet UL 5 flame spread rating with average smoke rating less than 165. (UL 723)

Coolers – FIP Polyurethane

All wall and ceiling insulation will be 4″ thick, high quality, foamed in-place polyurethane, 2.2 lb density. K factor of not less than .141 and an R-factor of not less than 7.1 per inch, initial

fresh R-28.4 minimum total wall R factor. Vapor transmission will be less than 1 perm and foam core material must meet: UL Foam Core 25 flame spread rating with average smoke rating less than 450 (ASTM E-84). UL 1715 Certified listed with Intertek/ETL (optional).

PASSAGE DOORS

Door will be flush mounted, positioned and hinged per drawings. Doors will be provided with suitable sweep and magnetic gaskets. Door will be provided with door closer, one pre-wired vapor proof light fixture, light switch with pilot light, dial thermometer, manual internal lock override, chrome plated cam lift hinges, and chrome plated door latches with strike. Doors on outdoor walk-ins will have a weather protected light switch and door drip cap. (Standard door opening size is 34″x76″; alternate sizes are available upon request.)

Door Options: Customer shall specify requirements for 3 hinges, view windows, locking bars, internal ramps, external ramps, and diamond tread plate.

Optional Doors: Optional sliding and overhead doors are available upon customer request.

GLASS DOORS

Glassdoor openings will be provided as necessary for the doors being installed. Sill height will be per customer specification. Wood framing of the opening will be required to assist with the installation of the glass doors.

RAIN ROOF PACKAGE

(For use on walk-ins installed outside. Specify whether walk-in is freestanding or which wall is butted.) A single-ply membrane roof will be supplied to provide a water-resistant covering of the ceiling panels. Membrane material shall be provided in one complete roll designed for the size of the walk-in. No welding of seams will be required for installation.

SLOPED ROOF PACKAGE

(For use on walk-ins installed outside. May be required at certain snow loads; consult U.S. Cooler®/Brew Cave®.)

In order to form a sloped roof profile, suitable quantities of sloped foam will be provided. The foam will be cut in a manner that upon installation, a ¼”:1′ slope is obtained. The membrane roof will be increased in size appropriately, in order to provide the additional material required to properly cover the resultant profile.